Heliarc welding, also known as TIG welding, is a precision welding technique that utilizes a non-consumable tungsten electrode to create clean and high-quality welds. It is widely used for its versatility in welding various metals, including aluminum, stainless steel, and copper. The process involves a shielding gas to protect the weld area from contamination, resulting in strong, durable weld joints. Skilled craftsmanship and attention to detail are essential for mastering the art of heliarc welding. Dive into the world of precision welding with this comprehensive guide on what is heliarc welding.

What is Heliarc Welding: A Comprehensive Guide

Welcome to our in-depth exploration of heliarc welding, a fascinating process that plays a crucial role in joining metal components together. Whether you are a curious student or an aspiring welder, this article will walk you through the ins and outs of heliarc welding, also known as Tungsten Inert Gas (TIG) welding.

The Basics of Heliarc Welding

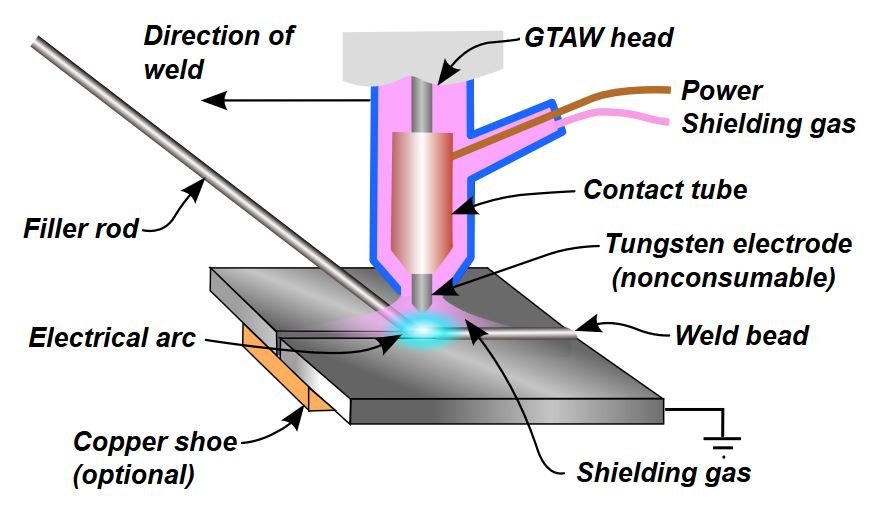

So, what exactly is heliarc welding? Heliarc welding is a specialized welding technique that uses a non-consumable tungsten electrode to create the weld. The term “heliarc” comes from the use of helium gas as one of the inert gases in the welding process. In addition to helium, argon gas is commonly used in heliarc welding to shield the weld area from atmospheric contamination.

Unlike other welding methods that use a consumable electrode, heliarc welding requires a steady hand and precise control. The tungsten electrode produces a high-temperature arc that melts the base metal and filler rod, creating a strong and clean weld.

The Equipment Used in Heliarc Welding

Before delving deeper into how heliarc welding works, let’s first familiarize ourselves with the equipment used in this process. The primary components of a heliarc welding setup include:

- Tungsten electrode

- Welding torch

- Gas cylinder (helium or argon)

- Power source

- Filler rod

The tungsten electrode plays a crucial role in heliarc welding by generating the arc that melts the metal. The welding torch directs the heat from the electrode to the workpiece, while the gas cylinder provides the shielding gas to protect the weld pool. The power source supplies the necessary current to sustain the welding arc, and the filler rod is used to add material to the weld joint.

Advantages of Heliarc Welding

Now that we have a basic understanding of what heliarc welding entails, let’s explore some of the key advantages of this welding technique:

- High Precision: Heliarc welding allows for precise control over the welding process, making it ideal for intricate welds and delicate materials.

- Clean Welds: The use of inert gases in heliarc welding results in clean and aesthetically pleasing welds with minimal spatter.

- Strong Joints: Heliarc welding produces high-quality welds with excellent strength and durability, making it suitable for critical applications.

- Versatility: Heliarc welding can be used on a wide range of materials, including stainless steel, aluminum, and titanium, making it a versatile choice for various projects.

Applications of Heliarc Welding

Due to its precision and versatility, heliarc welding finds numerous applications across various industries. Some common applications of heliarc welding include:

- Automotive manufacturing

- Aerospace industry

- Shipbuilding

- Structural fabrication

- Precision instrument manufacturing

Getting Started with Heliarc Welding

If you’re interested in learning heliarc welding, it’s essential to start with the basics and practice diligently to master this intricate technique. Here are some tips to help you get started:

- Invest in Quality Equipment: Start with a reliable welding machine and high-quality tungsten electrodes to ensure smooth and consistent welding.

- Practice Proper Technique: Focus on maintaining a steady hand and precise control of the welding torch to create clean and strong welds.

- Experiment with Different Materials: Try welding various materials to understand how they react to the welding process and develop your skills further.

- Seek Guidance from Experts: Don’t hesitate to seek guidance from experienced welders or enroll in welding classes to hone your skills and learn advanced techniques.

Remember, mastering heliarc welding takes time and dedication, but the rewards are well worth the effort. With practice and perseverance, you can become a skilled heliarc welder capable of creating high-quality welds on a wide range of materials.

Whether you’re pursuing welding as a career or a hobby, heliarc welding is a valuable skill to have in your arsenal. So, roll up your sleeves, grab your welding torch, and dive into the world of heliarc welding!

Thank you for joining us on this journey to explore the intricacies of heliarc welding. We hope this guide has shed light on what heliarc welding is all about and inspired you to delve deeper into the art of welding.

Heliarc Welding

Frequently Asked Questions

What is Heliarc welding?

Heliarc welding, also known as Tungsten Inert Gas (TIG) welding, is a welding process that uses a non-consumable tungsten electrode to produce the weld. The electrode and the weld pool are protected from atmospheric contamination by an inert shielding gas, typically argon or helium.

How does Heliarc welding differ from other welding processes?

Heliarc welding differs from other welding processes in that it creates the weld by heating the workpieces with the electric arc created between the tungsten electrode and the workpiece. This process allows for more precise control over the weld, making it suitable for welding thin materials and producing high-quality welds.

What are the benefits of using Heliarc welding?

Some benefits of using Heliarc welding include producing clean and precise welds, excellent control over the welding process, minimal spatter, and the ability to weld a wide variety of metals, including aluminum, stainless steel, and copper.

Can beginners learn Heliarc welding?

Yes, beginners can learn Heliarc welding with proper training and practice. It requires skill and coordination to control the welding torch, filler rod, and foot pedal simultaneously. Taking a welding course or receiving hands-on instruction can help beginners master the techniques required for Heliarc welding.

Final Thoughts

In conclusion, Heliarc welding, also known as TIG welding, is a precise welding process that produces high-quality welds. The technique uses a non-consumable tungsten electrode to create the weld, which results in clean and strong welds. Heliarc welding is commonly used for welding thin materials and in industries where high precision is required. Overall, Heliarc welding is a versatile and effective method that is known for its quality and precision in welding applications.